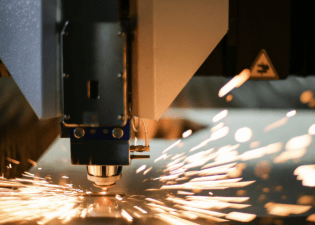

Industry Application

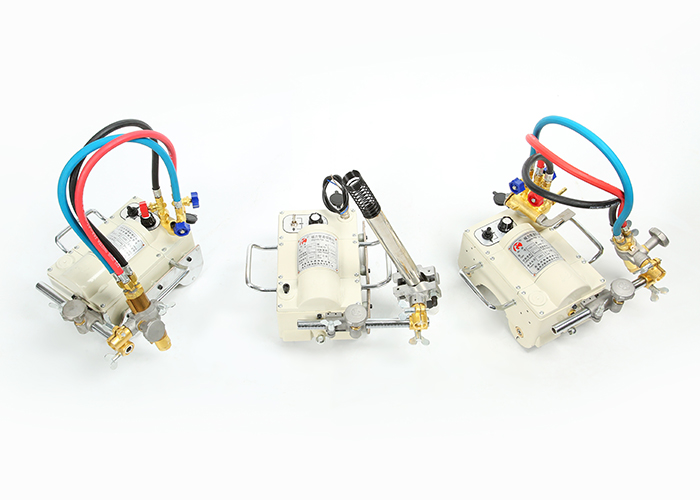

With the continuous advancement of industrial technology, professional welding and cutting equipment is increasingly used in many fields and plays an indispensable role. Such equipment is widely used in industries such as petrochemicals, shipbuilding, automobile manufacturing, construction engineering, metallurgy, railways and aerospace to meet the needs of high-quality and high-precision welding and cutting in different fields.

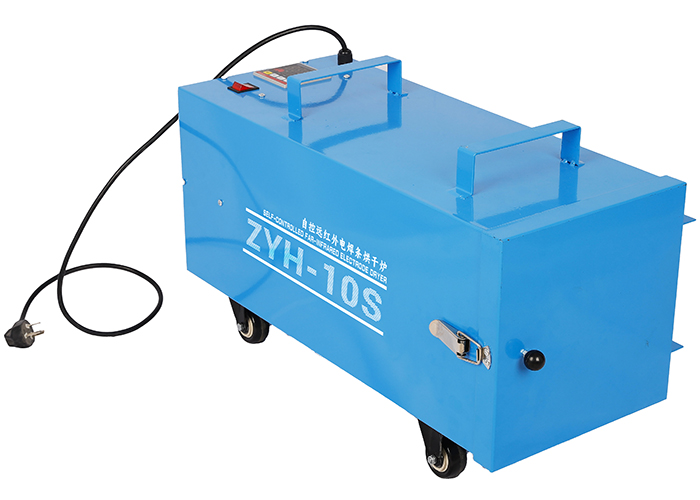

RETO-Trusted Supplier of Welding and Cutting Equipment

Reto Company is constantly striving for growth and innovation. We are actively expanding our product line to meet our customers' diverse needs. Through extensive research and development, we introduce new and improved products that offer enhanced functionality and value. As a reliable supplier, we have a proven track record of delivering high-quality products on time. Our dedicated team is committed to meeting customer needs and providing excellent service. With our expertise and dedication, you can trust us to be your dependable partner for cutting and welding equipment.

Application fields and solutions of professional welding and cutting equipment

The following will introduce in detail the importance of welding and cutting equipment in various major application fields and provide corresponding solutions.

Petrochemical Industry

In the petrochemical industry, the welding quality of equipment and pipelines directly affects the safety and efficiency of production. Due to the complexity of chemical plants and the particularity of the operating environment, this field requires high-reliability and corrosion-resistant welding and cutting technologies.

Solution:

Provide equipment with automated welding functions to ensure welding quality and stability.

Use anti-corrosion materials and high-temperature-resistant equipment to ensure the safety of equipment in extreme environments.

Provide high-precision cutting technology for pipeline systems to ensure the tightness of pipeline connections and the safety of fluid transportation.

Shipbuilding and marine engineering

The shipbuilding industry has particularly strict requirements on welding equipment, especially in the construction of large hulls and offshore platform structures, which require efficient and precise welding processes. The corrosion resistance and fatigue resistance of the welding parts are crucial to the service life of the hull.

Solution:

Provide anti-corrosion welding equipment that adapts to the marine environment to extend the service life of the welded structure.

Improve hull welding efficiency, reduce labor costs, and improve work accuracy through robotic automatic welding systems.

Provide welding quality certification that meets international ship safety standards to ensure product safety and stability.

Automobile manufacturing

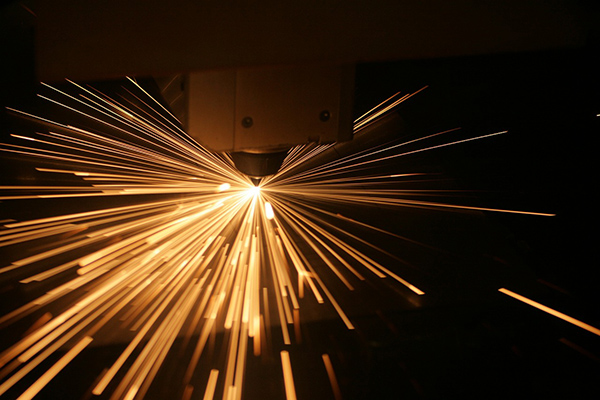

In the field of automobile manufacturing, welding and cutting technology is used in the assembly process of parts such as bodies, chassis, and doors. Welding accuracy and efficiency directly affect the cycle and quality of automobile production.

Solution:

Adopt intelligent automatic welding equipment to improve production efficiency while ensuring welding accuracy.

Provide robot laser cutting equipment to achieve fast and high-precision cutting of body panels.

Provide modular solutions to enable welding equipment to flexibly adapt to the production needs of different models.

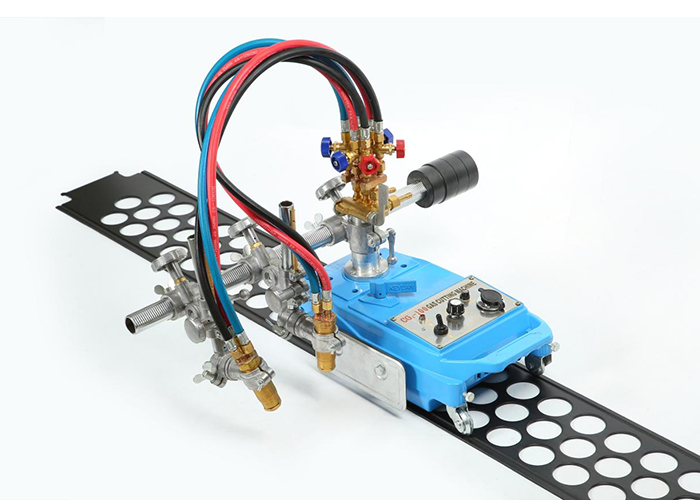

Construction engineering

The demand for welding and cutting equipment in the construction industry is concentrated in the construction process of steel structures, bridges, and high-rise buildings, requiring welded structures to have high strength and stability.

Solution:

Provide portable welding equipment that is suitable for the mobility work needs of construction sites.

Adopt welding technology that meets seismic requirements to ensure the durability and safety of building structures.

For bridge and steel structure projects, provide efficient thick plate welding and cutting equipment to improve construction efficiency.

FAQ For Reto

We are very confident in our products, all goods have 100% check before packing, we make sure all the goods we sent out to customers are in good condition ( Except for the damages caused by the uncontrolled factors during the transportation). When customers receive the goods in one year, if there are quality problems, please tell us and show us the detail proof so we can check and give replacement in the next order.

Proofreading is usually 5-7 working days. If the order reaches or exceeds the MOQ quantity, the proofing fee is refunded. If not reached behind MOQ quantity, proofing fee will be taken by your side.

The freight depends on weight, packing size and your country or province region, etc. You can confirm slipper by photo and video to save this money if you become our customer.

We are the manufactory specialized in this field many years, in Wenzhou, Zhejiang Province, China. Our factory have passed ISO9001, and CE certificate.

- Rapid Delivery Worldwide

- Articles enjoy worldwide warranty

- Quick response before, during and after sales

Feel Free To Contact Us

Our experts are ready to discuss your specific requirements and recommend customized solutions to you

Contact us today to get our engineering support and customer service.