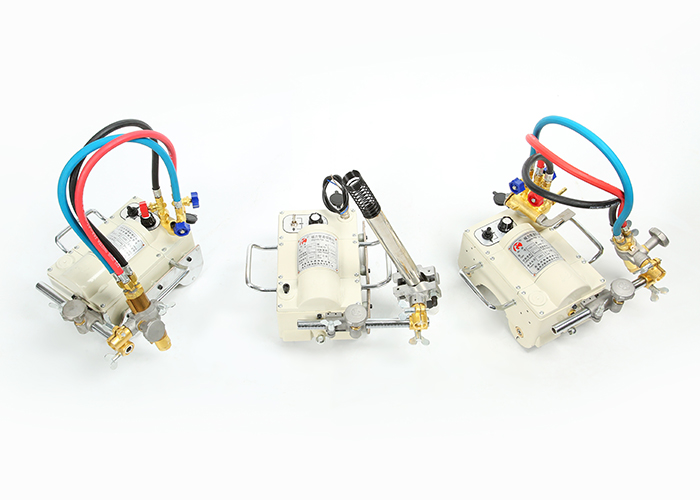

CG2-11K Magnetic Pipe Plasma Cutter

CG2-11K pipecut magnetic machine and bevelling machines are the economical solution for cutting and bevelling pipe from 350mm upwards.

CG2-11K Magnetic Pipe Plasma Cutter Detail Display

CG2-11K Magnetic Pipe Plasma Cutter

CG2-11K Magnetic Pipe Plasma Cutter

CG2-11K Magnetic Pipe Plasma Cutter

CG2-11K Magnetic Pipe Plasma Cutter

Products Description

CG2-11K pipecut magnetic machine and bevelling machines are the economical solution for cutting and bevelling pipe from 350mm upwards.Our equipment is certified to CE and ISO 9001 standards, ensuring full compliance with international safety and quality requirements.

Key Features

| 1.The main body is made of aluminum alloy, light, and portable. | 4.Especially for pipe cutting, convenient in operation. |

| 2.It adopts permanent magnet wheel to crawl on the pipe while cutting. | 5.Beveling range: I.Y.V 45° |

| 3.Can be used for parallel, upright and face upward cutting. | 6.Widely applied to oil production, chemical pipe project. |

Product Information

| No. | Description |

| 1 | Body |

| 2 | Cross Feeding Hand Wheel: To adjust horizontal position of torch |

| 3 | Hoses: Connect them to gas distributor. There are three hoses: preheating oxygen hose, fuel gas hose and cutting oxygen hose |

| 4 | Torch(Gas Torch change to Plasma torch) |

| 5 | Adjusting Hand Wheel of Torch |

| 6 | Handlebar |

| 7 | Reversing Switch: To change the direction of machine. “STOP” position is in the middle |

| 8 | Thermal Baffle: To prevent heat to diffuse into the inner of machine |

| 9 | Two-port Valve: To adjust the flow |

| 10 | Gas distributor: Gases are preheating oxygen, fuel gas and cutting oxygen |

| 11 | Speed Regulating Knob: Decrease the speed along “10” toward “0” anti-clockwise |

| 12 | Plug Seat |

| 13 | Magnetic Roller Wheel: The two magnetic roller wheels can make the machine walk along pipe wall smoothly |

Product Parameter

|

Diameter of Circle Cutting |

CG2-11: >φ108mm |

|

Power Source |

220V 50HZ |

|

Cutting Speed |

50-750mm/min |

|

Cutting Thickness |

6-50mm |

|

Groove Angle |

0°-45° |

|

Cutting Range |

¢>108mm (The no-seam pipe) |

|

Cutting Accuracy |

When the machine walks a cycle on pipe, the error is below 0.5mm every 1m circumference. The smoothness of cutting and groove can reach. |

|

Adsorption Affinity of Magnetic Roller Wheel |

>50kg |

|

Impulse of Machine |

When the machine walks up and down, it is below 0.5mm |

|

Remark |

If the diameter >600mm, you’d better use optional guide band. |

Advantages:

1.Efficient cutting:It can quickly and accurately cut pipes, improving work efficiency.

2.Magnetic attachment:The magnetic design allows it to firmly attach to metal pipes, ensuring stability during cutting and reducing the risk of accidents.

3.Versatility:Suitable for cutting various types and sizes of pipes, providing flexibility in different work scenarios.

4.Portability:Lightweight and easy to carry, making it convenient for use in different locations.

5.Durability:Made of high-quality materials, it is resistant to wear and tear and has a long service life.

6.User-friendly operation:Simple to operate, even for those with limited experience in pipe cutting.

7.Cost-effective:Offers good value for money with its reliable performance and reasonable price.

Application

Pipecut magnetic is suitable for cutting and beveling cutting of various seamless steel pipes in factories and mines such as petroleum, chemical, shipbuilding, power generation machinery, construction and installation. Due to the adsorption force of the magnetic wheel, the cutting machine can also perform all-position and multi-directional cutting in various spatial positions of horizontal, vertical, horizontal and vertical, and the cutting and beveling can be completed at one time, reduce labor intensity.

Certificate

CG2-11K Magnetic Pipe Plasma Cutter FAQ

Q1: What kind of products you made? Our main productions are gas cutting machines, welding ovens and portable welding rod dryers. Q2: May I have a look at your catalogue? Sure, you can send us mail ( [email protected]). Q3: What’s minimum quantity of an order of your goods? 1) Cutting machine: 10 sets Q4: How long does it usually take you to make delivery? The item if have stock, we can send you immediately. And others need to check your qty, usually our delivery time is 15-30 days after receiving your payment. If the goods have stock, it can be fast delivery by ups or FedEx Express, like 3-9 days receive after payment. Q5: How can I choose a suitable Portable Gas Cutter? Just tell us what kind of rail ttype do you need, straight line or circular rail? Q6:What shall we do if we don’t know how to operate the machine after purchase? We have detailed installation and operating instructions attached. It is very simple and we also have a 24-hour telephone and email support. And our engineers are also available for machinery service overseas but not for free. Q7: What can we do if the machine has a problem? 24 hours timely response by email and phone calls or engineers overseas service but not for free. Q8:What is a gas cutting machine? A gas cutting machine is a tool used to cut through metals. It uses a fuel gas (such as acetylene) and oxygen to create a high – temperature flame. The intense heat melts the metal, and a jet of oxygen blows away the molten material, leaving a clean cut. Q9:What types of gases are used in a gas cutting machine? The most common fuel gas is acetylene. It burns with a very hot flame when combined with oxygen. Other fuel gases like propane and natural gas can also be used, but acetylene is preferred for its high heat output. Oxygen is always used as an oxidizer to support combustion and to blow away the molten metal. Q10:How do I set up a gas cutting machine? First, ensure that the gas cylinders (one for fuel gas and one for oxygen) are securely fastened in an upright position. Connect the hoses to the appropriate regulators on the cylinders and then to the torch. Adjust the regulators to set the correct gas pressures as recommended by the torch manufacturer. Usually, you need to purge the lines to remove any air before ignition. Q11:What safety precautions should I take when using a gas cutting machine? Wear appropriate personal protective equipment (PPE), including safety goggles, fire – resistant gloves, and a welding apron. Make sure the work area is well – ventilated to avoid inhaling fumes. Keep a fire extinguisher nearby and be aware of any flammable materials in the vicinity. Check for gas leaks regularly by using a soapy water solution on the connections. Q12:How do I maintain a gas cutting machine? Regularly clean the torch tip to remove any spatter or debris that can affect the quality of the flame. Check the hoses for any signs of wear or damage and replace them if necessary. The regulators should be calibrated periodically to ensure accurate gas flow. Also, store the gas cylinders in a cool, dry place when not in use. Q13:Can a gas cutting machine cut all types of metals? It can cut most ferrous metals (metals that contain iron), such as steel and cast iron. However, it may not be as effective for cutting non – ferrous metals like aluminum and copper. Special techniques or different equipment may be needed for non – ferrous metals due to their different thermal and chemical properties.

2) Portable welding dryer: 100pcs.

3) Oven: 10 sets.

- +8618858825816

- [email protected]

- No.39, Sitong Road, Zhuangquan Country, Tianhe Street, Wenzhou Economic And Technological Development Zone, Wenzhou City, Zhejiang Province, China

CG2-11K Magnetic Pipe Plasma Cutter More About Reto

Company Profile

Application Areas

Packaging & Transportation