HK-93-II Head-face Profiling Cutting Machine

HK-93-II is a kind of portable automatic gas-cutting machine, and you can know from its name “ Eagle cutting machine” that it is characterized by rapid moving,convenient,and easy to fast turning .

Products Description

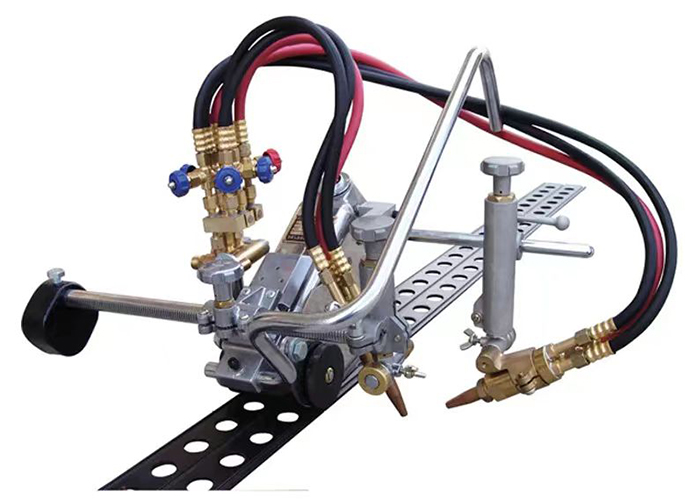

HK-93-II is a kind of portable automatic gas-cutting machine, and you can know from its name, “Eagle Cutting Machine,” that it is characterized by rapid moving, convenience, and easy to fast turning. It is widely used, has a proper structure, and is good-looking. Its operability and durability have been well improved after years of using and under some customers’ guidance.

Key Features

1. This head-face profiling cutting machine has two sets of touches that can bevel an X-shape at the end of the plate (both sides) at the same time and form in a single pass.

an X-shape at the end of the plate (both sides) at the same time and form in a single pass.

2. The head-face profiling cutting machine has swiftness of motion and flexibility of operation.

3. This head-face profiling machine is equipped with a gas pre-set switch so as to avoid readjusting when cutting.

4. At the bottom and two sides of the machine is equipped with the thermal baffle so

as to prevent the machine from the heating radiation. This consequently provides stable walking and high quality in beveling X-shape.

Certification Marks: Certified with CE and ISO 9001, ensuring compliance with international safety and quality requirements.

Product Information

|

1. Adjusting handle: When traversing the handle, the torch moves left or right. |

8. Adjusting handle: Adjust the moving speed. |

|

2. adjusting handle: When traversing the handle, the torch moves up or down. |

9. Power socket |

|

3. Contrate gear rack |

10. Cutting the oxygen switch. |

|

4. Thermal baffle: Stop the thermal diffuse outside. |

11. Gas delivery hose. |

|

5. balance-weight |

12. Normal-reverse switch. |

|

6. two-port valve: Adjust the gas flow rate. |

13.Universal wheel |

|

7. On-off handle: Hold tightly the machine is off and hold loosely the machine is automatically on. |

14. cutting nozzle |

Product Parameter

|

Model |

HK-93-II |

|

Weight (body) |

8.5 KG |

|

Accessory |

3.8 KG |

|

Machine dimension |

420×290 ×250H(mm) |

|

Speed control |

SCR control |

|

Power source |

AC 220V±10% |

|

Cutting speed |

50~1000mm/min |

|

Cutting thickness |

5-30mm |

|

Bevel angle |

0~45° |

|

Diameter of the cutting circle |

Φ50~Φ550mm |

|

Tip |

G02 (for acetylene) or G03 (for propane) |

|

Motor |

DC110V 50HZ 30W 4200RPM |

Advantages:

The HK-93-II head-face profiling cutting machine has the following advantages:

1. High portability: The main body is relatively lightweight, generally weighing around 8.5 kilograms. With accessories, the total weight is also moderate, making it easy for operators to carry and move. It can be conveniently transported between different work sites and is suitable for various work scenarios, especially those with limited space or where frequent changes of work location are required.

2. Flexible and convenient operation: The cutting torch can be adjusted in multiple directions flexibly. For example, by adjusting the handle, the cutting torch can be moved left and right and up and down to quickly and accurately align with the cutting position, meeting the cutting needs of various complex shapes.

The machine has an automatic switch function, making operation simple. For instance, through a special switch design, when the machine is gripped, it is in the off state, and when released, it automatically turns on, allowing the operator to control the start and stop of the machine at any time.

3. High cutting precision: Equipped with a precise control system, such as a thyristor-controlled speed regulation system, which can ensure stable cutting speed and thus guarantee cutting precision.

It can perform profiling, cut along a template, and accurately replicate the shape and size of the template. It is very suitable for processing workpieces with high requirements for shape and size precision, especially for mass production of cutting parts of the same shape.

4. Wide application range: applicable to the cutting of various materials. For example, it is suitable for multiple gases, such as oxygen, acetylene gas, or liquefied petroleum gas, and can meet the cutting needs of different materials, including metal materials such as steel plates.

Widely used in multiple industries such as shipbuilding, petroleum, metallurgy, and metal structure processing. It can complete the cutting of various shapes of parts well.

5. High cutting efficiency: It has a relatively fast cutting speed, with a cutting speed of 50-1000 millimeters per minute, which can complete the cutting work in a short time and improve work efficiency.

It can simultaneously perform X-shaped groove cutting on the upper and lower surfaces of the end of the steel plate. Compared to some equipment that can only cut on one side, it greatly saves processing time.

6. Reasonable structural design: The overall structure is compact, and the appearance design is beautiful and generous. The layout of each component is reasonable, which is convenient for operation as well as maintenance and repair.

Equipped with components such as a heat baffle, which can effectively prevent heat from spreading to the outside. It not only protects the safety of operators but also reduces the impact of heat on the surrounding environment and other equipment.

7. High cost performance: Compared to some large-scale, high-precision cutting equipment, the price of the HK-93-II is relatively affordable. At the same time, its performance and functions can meet the needs of most users, making it have high cost performance and suitable for small and medium-sized enterprises or individual users.

Certificate

HK-93-II Head-face Profiling Cutting Machine FAQ

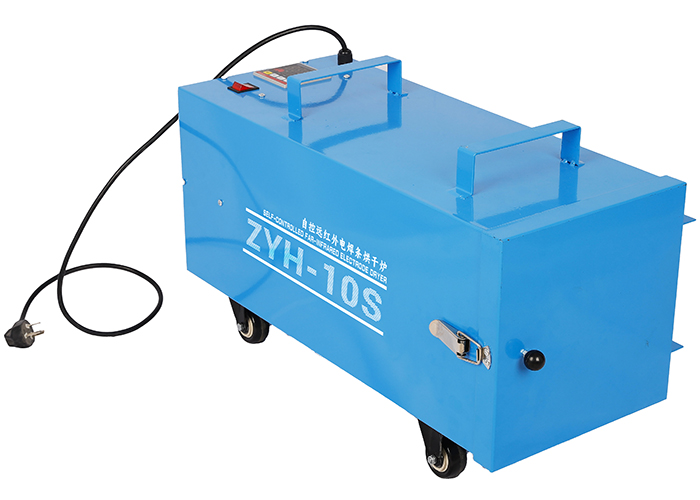

Q1: What kind of products you made? Our main productions are gas cutting machines, welding ovens and portable welding rod dryers. Q2: May I have a look at your catalogue? Sure, you can send us mail ( [email protected]). Q3: What’s minimum quantity of an order of your goods? 1) Cutting machine: 10 sets Q4: How long does it usually take you to make delivery? The item if have stock, we can send you immediately. And others need to check your qty, usually our delivery time is 15-30 days after receiving your payment. If the goods have stock, it can be fast delivery by ups or FedEx Express, like 3-9 days receive after payment. Q5: How can I choose a suitable Portable Gas Cutter? Just tell us what kind of rail ttype do you need, straight line or circular rail? Q6:What shall we do if we don’t know how to operate the machine after purchase? We have detailed installation and operating instructions attached. It is very simple and we also have a 24-hour telephone and email support. And our engineers are also available for machinery service overseas but not for free. Q7: What can we do if the machine has a problem? 24 hours timely response by email and phone calls or engineers overseas service but not for free. Q8:What is a gas cutting machine? A gas cutting machine is a tool used to cut through metals. It uses a fuel gas (such as acetylene) and oxygen to create a high – temperature flame. The intense heat melts the metal, and a jet of oxygen blows away the molten material, leaving a clean cut. Q9:What types of gases are used in a gas cutting machine? The most common fuel gas is acetylene. It burns with a very hot flame when combined with oxygen. Other fuel gases like propane and natural gas can also be used, but acetylene is preferred for its high heat output. Oxygen is always used as an oxidizer to support combustion and to blow away the molten metal. Q10:How do I set up a gas cutting machine? First, ensure that the gas cylinders (one for fuel gas and one for oxygen) are securely fastened in an upright position. Connect the hoses to the appropriate regulators on the cylinders and then to the torch. Adjust the regulators to set the correct gas pressures as recommended by the torch manufacturer. Usually, you need to purge the lines to remove any air before ignition. Q11:What safety precautions should I take when using a gas cutting machine? Wear appropriate personal protective equipment (PPE), including safety goggles, fire – resistant gloves, and a welding apron. Make sure the work area is well – ventilated to avoid inhaling fumes. Keep a fire extinguisher nearby and be aware of any flammable materials in the vicinity. Check for gas leaks regularly by using a soapy water solution on the connections. Q12:How do I maintain a gas cutting machine? Regularly clean the torch tip to remove any spatter or debris that can affect the quality of the flame. Check the hoses for any signs of wear or damage and replace them if necessary. The regulators should be calibrated periodically to ensure accurate gas flow. Also, store the gas cylinders in a cool, dry place when not in use. Q13:Can a gas cutting machine cut all types of metals? It can cut most ferrous metals (metals that contain iron), such as steel and cast iron. However, it may not be as effective for cutting non – ferrous metals like aluminum and copper. Special techniques or different equipment may be needed for non – ferrous metals due to their different thermal and chemical properties.

2) Portable welding dryer: 100pcs.

3) Oven: 10 sets.

- +8618858825816

- [email protected]

- No.39, Sitong Road, Zhuangquan Country, Tianhe Street, Wenzhou Economic And Technological Development Zone, Wenzhou City, Zhejiang Province, China

HK-93-II Head-face Profiling Cutting Machine More About Reto

Company Profile

Application Areas

Packaging & Transportation