HK-8SS HK-8SS welding automatic trolley

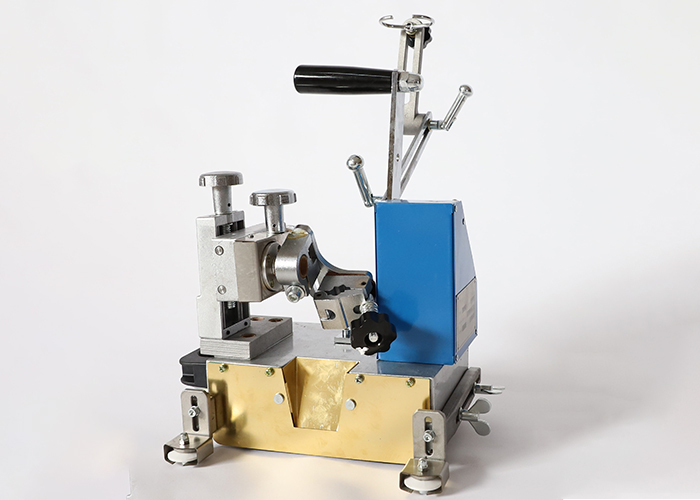

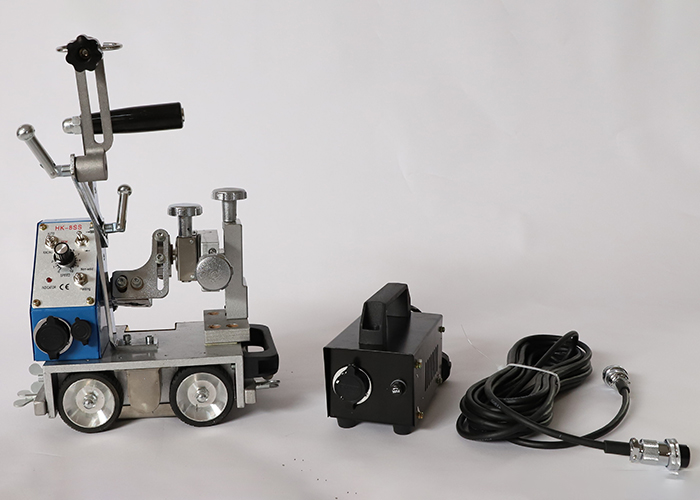

HK-8SS welding automatic trolley consists of car body, X-Y slider, guide wheel, gun handle, gun oscillator, control box and other components.

HK-8SS HK-8SS welding automatic trolley Detail Display

HK-8SS HK-8SS welding automatic trolley

HK-8SS HK-8SS welding automatic trolley

HK-8SS HK-8SS welding automatic trolley

Products Description

HK-8SS welding automatic trolley consists of car body, X-Y slider, guide wheel, gun handle, gun oscillator, control box and other components. Car body part: it is the frame of the whole machine and the carrier of other parts.

Key Features

- The machine is compact in size, lightweight, and easily portable and installable.

- The car is equipped with a dust-proof and anti-magnetization transmission system, featuring a simple structure and long service life.

- It utilizes four-wheel drive simultaneously, with high-quality combined rubber wheels that offer excellent resistance to high temperatures and stable welding performance.

- The trolley track can be customized or welded onto the base material, allowing for horizontal fillet welding; it is particularly suitable for welding inside large pipelines.

- This equipment finds extensive applications in ships, bridges, petrochemical pipeline engineering projects, among others.

Certification Marks:

Certified with CE, ISO 9001, ensuring compliance with international safety and quality requirements.

Pduct Informationro

| 1.Control panel | 8.Base |

| 2.Control box: can adjust all actions of the car, refer to the “ControlPanel Instructions” for details. |

9.Motor housing |

| 3.Handle: Pull the handle up while moving the machine. | 10.Gun holder assembly: It is the holding device of the welding gun, which can be easily repaired, adjusted and disassembled. |

| 4.X-Y mobile slider: device for adjusting the position of welding gun, during welding, the welding gun can be fine-tuned from top to bottom. |

11.Welding gun |

| 5.Plastic handle | 12.Heat Shield |

| 6.Guide Rod | 13.Guiding pulley: A device that rolls along the base metal surface to guide the precise welding area. |

| 7.Traveling Wheel |

Product Paramenters

Main technical parameters:

| 1. Outline Dimensions: | 215mm×275mm×215mm | |

| 2. Machine weight: | 8.5Kg | |

| 3. Supply Voltage: | Input AC 220V/Output DC 24V | |

| 4. Power: | 22W | |

| 5. Adsorption: | 10~25Kg | |

| 6. Welding speed: | 150~900mm/min | |

| 7. Adjustment range of welding gun |

Up and down: | 50mm |

| left and right: | 50mm | |

| Operating angle: | ±45° | |

| Carry out angle: | 10° | |

| Rotation angle: | 360° | |

Advantages:

The HK-8SS welding automatic trolley is a highly efficient and practical welding equipment with the following characteristics:

1.Components and structure:

• Car body: It is sturdily constructed to provide a stable platform for the welding process.

• X-Y slider: Enables precise movement in multiple directions, allowing for accurate welding along different paths.

• Guide wheel: Helps the trolley move smoothly along the welding surface, ensuring consistent welding.

• Welding gun handle: Designed for easy manipulation and control of the welding gun, enhancing the welder’s operating experience.

• Welding gun swinging device: Facilitates the necessary movement of the welding gun during the welding process, enabling better access to the welding area and improving welding quality.

• Control box: Allows for convenient control and adjustment of various welding parameters such as speed, welding current, and other settings.

2.Performance advantages:

• Automated welding: Significantly reduces the labor intensity of welders by automating the welding process. It can maintain a stable welding speed and ensure the uniformity and consistency of welds, improving the overall welding quality.

• Magnetic design: Equipped with strong permanent magnet guide wheels and an anti-magnetization transmission system. This design enables the trolley to firmly adhere to the welding surface, especially for ferromagnetic materials, ensuring accurate welding and preventing deviations during the welding process.

• Gear drive: Adopts a gear drive system, which is more stable and reliable compared to traditional chain drive systems. It can avoid the problems of looseness and vibration in the running process, ensuring smooth and precise movement of the trolley.

• Adjustable speed: The welding speed can be adjusted according to different welding requirements, providing flexibility for various welding tasks.

3.Portability and ease of use:

• Small size and light weight: The HK-8SS welding automatic trolley is compact in size and lightweight, making it easy to move and install in different workplaces. It is convenient for welders to use in various working environments, such as construction sites, workshops, and shipyards.

• User-friendly operation: The operation of the trolley is relatively simple and easy to learn. Even welders with relatively little experience can quickly master its operation methods, improving work efficiency.

4.Versatility:

• Welding applications: It is suitable for a wide range of welding processes, including MIG welding, and can be used for vertical angle welding and horizontal angle welding. It is widely applied in industries such as shipbuilding, bridges, locomotives, petrochemicals, and steel structure engineering for welding structures like stiffened web plates, ribbed plates, cross positions, and boxing beams.

5.Other advatages:

• Good dustproof effect: The internal structure of the trolley is designed with dustproof measures, which can effectively prevent dust and impurities from entering the equipment, prolonging the service life of the trolley.

• Parameter display: Some models may be equipped with a digital display screen to show various welding parameters, making it convenient for welders to monitor and adjust the welding process in real-time.

HK-8SS HK-8SS welding automatic trolley FAQ

Q1: What types of welding carrages avaible? A: There are horizontal welding carriage, vertical welding carriage, gigid track welding carriage, flexible track welding carriage and so on. Q2: How to choose the right welding carriage? A:When choosing the right welding carriage, consider the following factors: 1.Welding Process – Determine the welding process you will be using. Different welding carriages are designed for specific processes such as MIG/MAG, TIG, or submerged arc welding. Make sure the carriage is compatible with your chosen welding method. 2.Workpiece Characteristics – Consider the size, shape, and material of the workpieces. For large and heavy workpieces, a carriage with a higher load capacity may be required. If you are welding on curved surfaces or irregular shapes, a flexible track carriage might be more suitable. – The material being welded can also influence the choice. Some carriages are better suited for certain materials, so ensure the carriage can handle the specific metal or alloy you are working with. 3.Welding Environment – If you are working in an outdoor or harsh environment, a rugged and weather-resistant welding carriage might be necessary. Pneumatic carriages can be a good choice in dusty or wet conditions. – For indoor use or areas with strict environmental requirements, an electric welding carriage with low noise and no pollution is a better option. 4.Precision and Quality Requirements – If high precision and quality welds are essential, look for a carriage with accurate positioning and control features. Rigid track carriages often provide better precision than flexible ones. – Consider the need for adjustable welding parameters and controls to ensure consistent weld quality. 5.Budget – Set a budget for your welding carriage purchase. There are a wide range of options available at different price points. Balance your requirements with your budget to find the best value for your money. By carefully considering these factors, you can choose a welding carriage that meets your specific welding needs and helps improve the efficiency and quality of your welding operations. Q3: How much does a welding carriage cost? A:The cost of a welding carriage can vary widely depending on several factors such as its type, features, quality, and brand. Here are some general price ranges: 1.Low-end models: Some basic or entry-level welding carriages can cost around $200 to $1,000. For example, simple magnetic or small portable welding carriages with limited functions and lower build quality might fall in this price range. 2.Mid-range models: These typically cost between $1,000 and $5,000. Mid-range welding carriages often have better build quality, more advanced features such as adjustable speed and welding parameters, and are suitable for a wider range of welding tasks. Models with flexible tracks or certain levels of automation might be in this category. 3.High-end models: Premium or high-performance welding carriages can cost $5,000 or more. These may be used in industrial settings that require high precision, complex welding operations, or have specific requirements for welding quality and productivity. Some advanced robotic welding carriages or those with sophisticated control systems and high-quality components can fall into this high-end price range. It’s important to note that prices can also vary depending on the supplier, region, and any additional accessories or features included with the welding carriage. When purchasing a welding carriage, it’s advisable to consider your specific welding needs and budget to find the most suitable option. Q4: Can I use seconde-hand welding carriages? A:You can use second-hand welding carriages, but there are several factors to consider: Advantages – Cost Savings: Second-hand welding carriages can be significantly cheaper than new ones, which can be beneficial if you’re on a tight budget. – Immediate Availability: You may be able to find a used carriage quickly, rather than waiting for a new one to be delivered or manufactured. Considerations – Condition: Thoroughly inspect the carriage for signs of wear and damage. Check the wheels, tracks, motor, electrical components, and welding torch holder. Look for cracks, bent parts, or excessive rust. – Functionality: Test the carriage if possible to ensure it operates smoothly and accurately. Check the speed control, direction control, and any adjustable features. Make sure the welding torch holder is secure and properly aligned. – Compatibility: Ensure that the used carriage is compatible with your welding equipment and processes. Check the voltage requirements, gas connections (if applicable), and any other specifications that may affect its use with your setup. – History and Maintenance: Try to find out the history of the carriage. Has it been properly maintained? Were there any major repairs or issues in the past? Ask for maintenance records if available. – Safety: Ensure that the used carriage meets all safety standards. Check for proper grounding, safety switches, and any other safety features. Make sure there are no electrical hazards or mechanical issues that could pose a risk to you or others. In conclusion, using a second-hand welding carriage can be a viable option if you carefully assess its condition, functionality, compatibility, and safety. However, it’s important to be cautious and make an informed decision to ensure that you get a reliable and useful piece of equipment. Q5: How to assemble a welding carriage? A:Assembling a welding carriage typically involves the following steps: 1.Gather all Components – Check that you have all the parts of the welding carriage, including the frame, wheels or tracks, motor (if applicable), welding torch holder, electrical components, and any accessories or fasteners. 2.Prepare the Workspace – Clear a clean and flat work area where you can assemble the carriage without obstructions. Have your tools handy, such as wrenches, screwdrivers, pliers, and any specialized tools required for the specific model. 3.Frame Assembly – Start by assembling the frame of the carriage. Follow the manufacturer’s instructions to connect the various pieces of the frame using bolts, screws, or welding if necessary. Ensure that the frame is square and stable. 4.Install Wheels or Tracks – Depending on the type of carriage, install the wheels or tracks. Make sure they are properly aligned and secured. Check for smooth rotation and proper fit. 5.Mount the Motor (if applicable) – If the welding carriage has a motor for movement, mount it securely to the frame. Connect the motor to the power source and any control systems according to the instructions. Test the motor to ensure it operates correctly. 6.Install the Welding Torch Holder – Attach the welding torch holder to the carriage. Adjust it to the desired height and angle, and make sure it is firmly fixed in place. Ensure that the torch can be easily inserted and removed. 7.Electrical Connections – If there are electrical components, such as switches, wires, and controllers, make the necessary electrical connections. Follow the wiring diagrams provided and ensure proper grounding for safety. Test the electrical functions to make sure everything is working as expected. 8.Final Checks and Adjustments – Once the assembly is complete, perform a final inspection of the welding carriage. Check for any loose parts, misalignments, or potential safety hazards. Make any necessary adjustments to ensure smooth operation and proper functionality. It’s important to note that the specific assembly steps may vary depending on the type and model of the welding carriage. Always refer to the manufacturer’s instructions for detailed and accurate assembly procedures. If you are unsure about any step, it may be helpful to consult an experienced welder or seek professional assistance. Q6:How do I ensure the safety of using a second-hand welding carriage? A:To ensure the safety of using a second-hand welding carriage, consider the following steps: Inspection – Thoroughly inspect the carriage for any visible damage. Check for cracks, bent parts, worn-out wheels or tracks, and loose connections. Look closely at the frame, motor housing, and welding torch holder. – Examine the electrical components. Check for frayed wires, damaged insulation, and proper grounding. Make sure all switches and controls are in good working condition. Functionality Test – If possible, test the carriage’s functionality before using it. Run it through its full range of motion to ensure smooth movement and proper operation of the motor (if applicable). Check the speed control and direction controls. – Test the welding torch holder to make sure it securely holds the torch and can be adjusted as needed. Maintenance and Repair – Perform any necessary maintenance or repair before using the carriage. Replace worn-out parts such as wheels, belts, or brushes. Tighten loose bolts and nuts. – If there are any electrical issues, consult a qualified electrician to ensure safe operation. Safety Features – Check for safety features such as emergency stop buttons, overload protection, and proper shielding. Make sure these features are in working order. – Use appropriate personal protective equipment (PPE) when operating the welding carriage, including welding helmets, gloves, and protective clothing. Research and Documentation – Try to obtain as much information as possible about the history of the carriage. Look for maintenance records, user manuals, or any safety certifications. – Research the make and model of the carriage to learn about any common safety issues or recalls. By following these steps, you can increase the safety of using a second-hand welding carriage and reduce the risk of accidents or injuries.

- +8618858825816

- [email protected]

- No.39, Sitong Road, Zhuangquan Country, Tianhe Street, Wenzhou Economic And Technological Development Zone, Wenzhou City, Zhejiang Province, China

HK-8SS HK-8SS welding automatic trolley More About Reto

Application Areas

CO2 welding automatic trolley is widely used in ship, bridge, locomotive, steel structure, petrochemical industry and other industries. It is suitable for welding various welding structures, such as: welding of reinforcing ribs, ribs, cross parts, welding of box girders, etc. Its main advantages are reducing labor intensity, improving working environment and improving work efficiency, which is 1.5 times higher than that of manual welding, avoiding poor quality of welds caused by human factors. Generally, poor rate of manual operation is about 20%, while automatic welding trolley does not produce poor rate of welding, so its comprehensive benefit is nearly 200% higher than that of manual welding.High degree of automation to ensure the stability of welding quality.

Packaging & Transportation

Company Profile